Understanding LTL freight pricing or LTL shipping cost is essential for any business that depends on reliable, cost-effective shipping.

In this quick guide to LTL freight pricing, we’ll review the basics and explore some of the finer points of LTL shipping, so you can identify every line item on your invoices and — better yet — explore opportunities to save on future shipments.

What is LTL freight?

LTL stands for “less than truckload.” It’s used when shippers don’t have enough freight to fill an entire truck trailer. It typically applies to loads of 150 to 15,000 pounds. There are several carriers, including regional and national LTL freight providers.

It’s a cost-effective way to ship. You only pay for the trailer space you use. It’s a win-win. However, it also introduces potential confusion when it comes to pricing. Shippers want to ensure the rate they’re paying for their truck space is fair. Additionally, they want it to be reasonably calculated and predictable.

How does LTL pricing work?

You might assume that LTL pricing is calculated by weight if you’re new to shipping. Or you might think LTL freight pricing is tied to the freight’s space on the truck. Like how a parking space costs the same price whether you’re using it for parking a Tesla, Ferrari, or Vespa.

But neither of these metrics quite captures the nuances of LTL pricing. Freight shipping operates differently from other industries, and with good reason. Rather than going by weight or volume alone, LTL pricing is based on a collection of factors. This includes total weight, distance traveled and — the critical metric — density. Here’s why.

Why density matters: Examples of LTL pricing in action

Here’s an example to help make this clearer.

If freight were priced purely by weight, shippers of heavier materials would bear the brunt of high shipping costs. But, at the same time, those shipping lighter goods would have an unfair advantage. For example, at a standard flat rate of $0.10 per pound, a bowling ball company would pay a lot more for their eight pallets of truck space than a maker of feather-filled pillows. Their LTL freight both occupies the same truck space but vastly different weights — and pricing.

The same issues arise when calculating LTL freight pricing on truck space alone. Although this method is used by some carriers (known as “pallet rates”), its inconsistencies make it less than ideal. This is particularly true for shippers with low-weight freight. If they find themselves paying as much for their 100-pound load as another shipper is paying for a 2,000-pound load, they’d likely look for other, more cost-effective options.

The basics of LTL freight pricing by density

Given the issues with weight and space, it’s not hard to see why density is typically the decisive factor (and for some carriers, the only factor) in calculating LTL pricing.

This approach was developed by the National Motor Freight Transportation Authority (NMFTA) as a way to fairly incorporate both weight and space into a pricing model that made sense for all parties. It relies on a simple formula that evaluates the length, width, and height of a shipment and calculates the weight in pounds, arriving at a measurement of pounds per cubic foot (PCF) for the shipment.

The NMFTA also has the National Motor Freight Classification (NMFC) to determine “Freight Class.” On the NMFTA website, the NMFC book has a list of commodity and the freight class associated with that commodity.

Use the NMFC book or contact a freight partner to help you assess your commodities to find their best-fit classes. There are a lot of nuances associated with Freight Class and a number of changes that have been made over the years, so it is important to stay on top of different changes to classes and subclasses. (Here is our guide to 2025 NMFC changes).

Density is measured by the number of Pounds per Cubic Foot (PCF) of each shipment. It takes the length x width x height (per 12 inches) and calculates the weight in pounds. Shipments can range from 1 PCF all the way to 50+ PCF.

To get better rate (per 100 pounds, known as CWT) with carriers, you want a higher density/PCF.

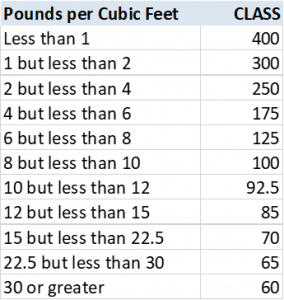

Shipments can then be organized and charged by PCF, according to an NMFTA classification system that ranks them from most dense (CL 50) to least dense (CL 500). In most cases, denser shipments are cheaper per pound than less dense shipments. But not always, since other factors can come into play when pricing LTL shipping rates for specific commodities. Below is the classification chart for these commodities.

*This is a range between CL 60 and CL 400. These density-based classes do not go up to CL 500, nor go down to CL 50.

Other factors affecting LTL pricing

Certain commodities, like perishable foods and ultra-fragile items, might require special handling or have other considerations that impact the overall price to ship them. This is where knowing the NMFC code of your freight is key to getting the best rates on your shipment.

These codes can be found in the NMFC Code Book, which establishes the standards for all LTL carriers and shippers. In the Code Book, commodities are assigned codes based on their density and the following three factors:

- Stowability: Applies to freight that is hazardous, heavy, or otherwise difficult to store

- Ease of Handling: Applies to freight that requires special handling

- Liability: Applies to freight that is perishable or easily damaged

But if you’ve ever received an unexpectedly high shipping invoice, you know that the additional factors don’t end there. LTL freight pricing can also include what are known as “accessorial charges and surcharges” for services including:

- Non-standard delivery to special, residential, or limited-access areas

- Weekend and evening deliveries

- Expedited and time-sensitive deliveries

- Hazardous materials handling

- Fuel surcharges based on current fuel rates and state taxes

How to get the best LTL pricing on your shipments

Now that you know the factors that affect LTL pricing, you can ensure that your shipments are being classed and charged correctly. What’s more, you’re in a prime position to negotiate for the best possible rates on your shipments. Depending on the type of freight you’re shipping, a density-only rate may be your best bet. Or you may be able to realize savings by looking up your freight’s NMFC code and going by the standard rate for your commodity class. And remember, you can always reach out to experts to provide insights into your LTL pricing and take advantage of every opportunity to increase efficiency and lower costs.

What to learn more? Request an analysis of your shipping today and see how you can be shipping more intelligently.